Stuffed cannelloni

Stuffed cannelloni production line up to 1000 pieces/hour.

Complete production line

Production line for stuffed cannelloni. From preparing the dough, to cooking, to forming the cannelloni. Production capacity 1000 pieces/hour.

The line includes the following machines:

- EP50 Extrusion press

- Pasta sheet calibrator

- Pasta sheets cooker

- Filling pump

- Forming and cutting belt for cannelloni

The production line is best suited for small and medium artisanal pasta makers.

Extrusion press

The machine

The EP50 double-tank kneading press allows the production of extruded pasta and pasta sheets. Thanks to the two independent tanks, the required dough can be produced continuously, even during the extrusion process.

The machine in the production line is equipped with an adjustable die, allowing the sheet thickness to be tuned before calibration.

Optional equipment

In addition, to ensure continuity of use and control over the final product, the press is combined with an external cooler for the extrusion chamber. This will keep the temperature of the dough constant without affecting the quality of the product.

Calibrator

After that, the sheet will pass through a calibrator.

This machine will finely adjust the thickness of the pasta sheet. This will optimize the cooking process of the dough according to the forming and sealing of the cannelloni.

In addition, this calibrator is equipped with two adjustable cutting discs, so as to divide the pasta sheet according to the desired size before cooking.

Pasta sheets cooker

Immersion pasta sheet cooker with stainless steel mesh.

Depending on the thickness of the dough and the desired product, the speed of the inner belt will be adjusted, varying the amount of time the sheet remains in boiling water.

The pasta sheet, exiting the cooker, will be cooled down with water at room temperature.

In adition, the cooker is designed for the connectionto the vacuum system, in order to remove excess steam.

Scraper

Once cooled down, the pasta sheet will pass through a scraper before the cutting and forming belt.

This process is needed to properly seal the stuffed cannelloni, removing excess starches and liquids, preparing the sheet for the next steps.

Filling pump

For the production of stuffed cannelloni, a filling pump will be needed to feed the forming belt.

This machine needs to be connected at the forming and cutting belt, that will extrude the filling on top of the processed pasta sheet.

The desired amount of filling can be adjusted by changing the working speed of the machine.

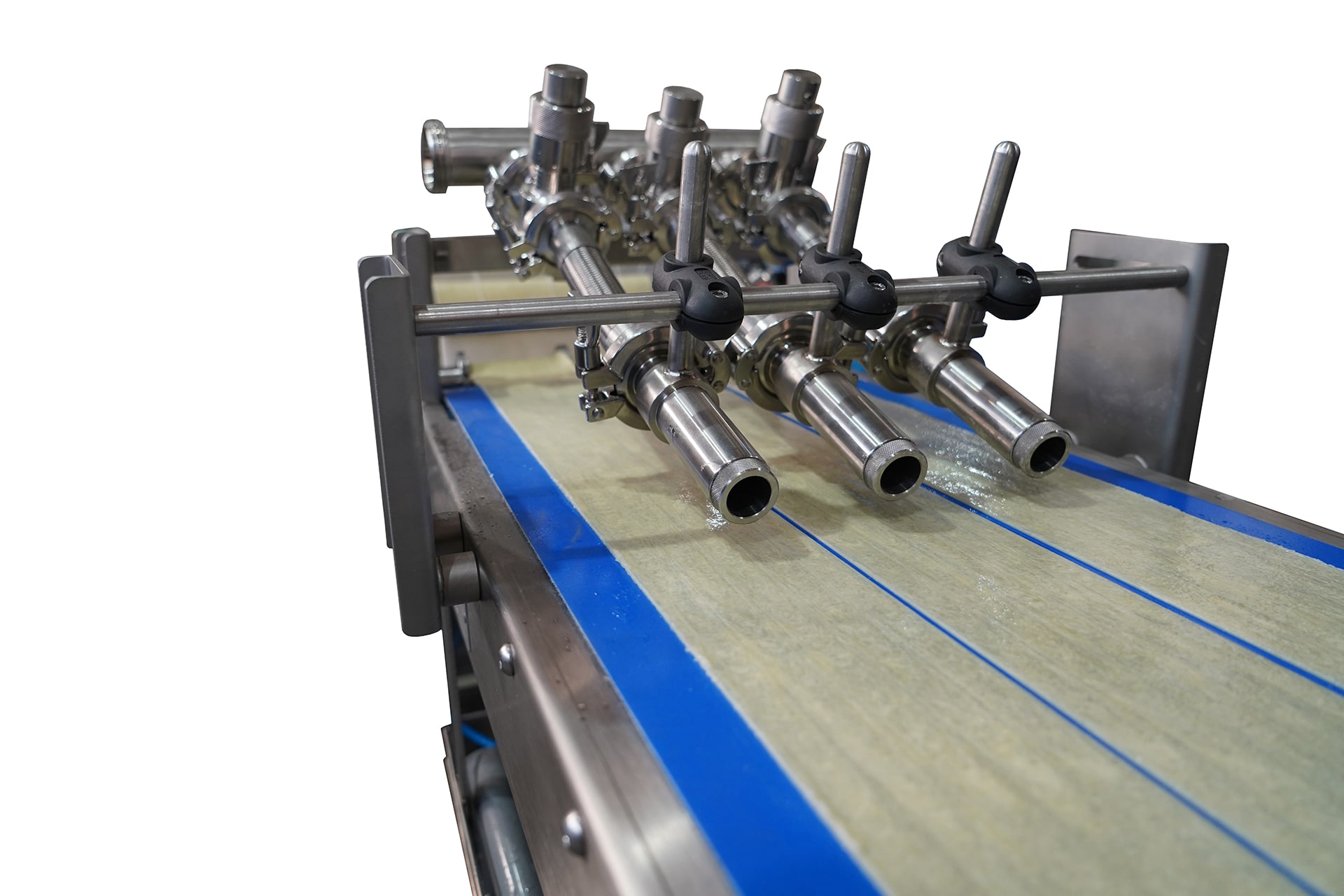

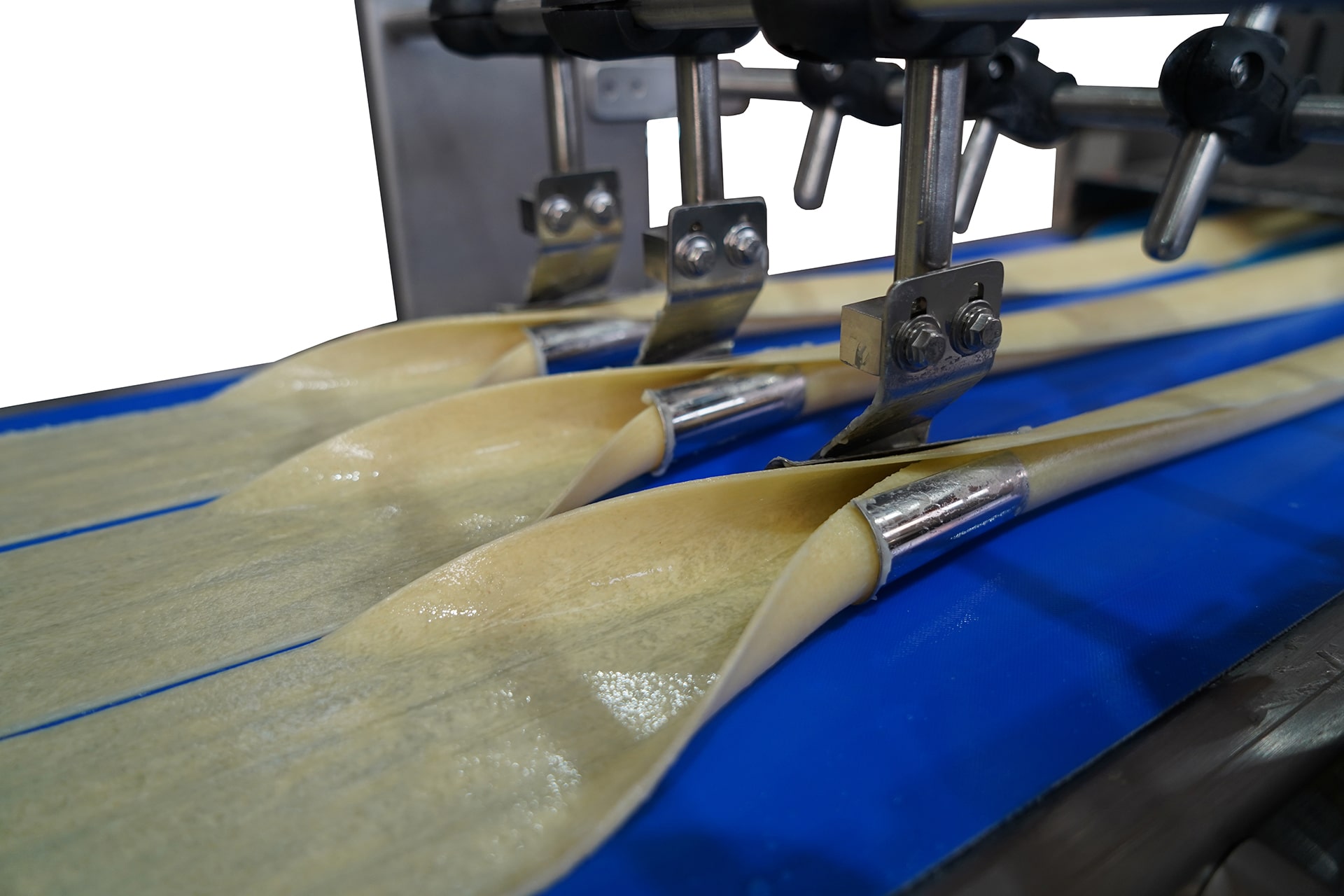

Filling extruders

Once on the forming belt, the filling will be extruded on the pre-cutted and scraped pasta sheet, combining the the output speed of the product with the speed of the conveyor belt.

The extruders are installed in a way that allows to finely adjust their position to ease the correct sealing of the product.

Cannelloni forming

Once the filling is extruded, la pasta sheet will be sealed on itself by two different devices.

The first one will form the classic cilindrical shape of the cannellone, tightening the dough around the filling.

The second forming device, on the other hand, will apply the correct pressure needed to close the product.

Cannelloni cutting unit

Once the product forming is over, an automatic cutting unit is placed on the end of the belt.

The knife of the cutting unit will be adjusted with a timer, so that the length of the finished cannelloni can be adjusted according to time intervals.

The cutting unit is equipped with all the necessary safety devices for safety precautionary regulations.

Video

Watch the video of the line in action.

Are you interested in a production line for larger quantities of product? Read the dedicated article about the 10000 pieces/hour stuffed cannelloni line.

Check out our video page to learn more about our pasta-making machines and equipment.